The Gehl V330 GEN:2 skid loader is a shining example of Gehl’s superior innovation and well thought-out product development.

- Emissions certified Tier IV engines combine power and efficiency.

- Self leveling lift action for better control of lifting loads.

- The new chassis aids in superior weight distribution, which further enhances stability. New rear bumper provides additional protection and towing capability.

- Thick steel plating and heavy-duty pins and bushings make this loader stronger than any other machine in its class.

- A heavily constructed vertical-lift boom provides substantial forward reach at trailer loading and dumping heights.

- Electronic engine control and foot throttle allow operation at part throttle, reducing sound levels and fuel consumption.

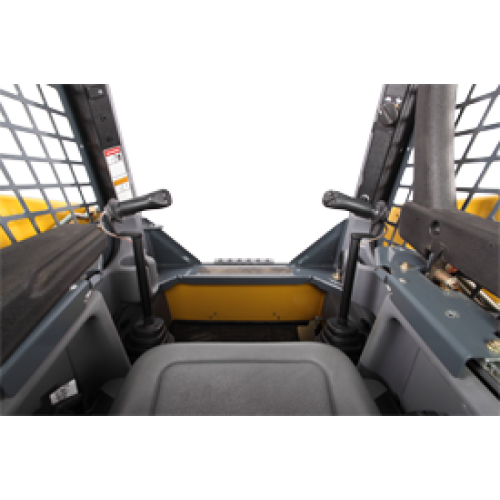

The operator’s compartment on the V330 GEN:2 skid loader provides a safe and comfortable working environment for operators of all sizes.

- Cab forward design enhances the view to the bucket. Level II FOPS is standard equipment.

- New side-folding restraint bar and armrests with multiple adjustments enhance operator safety and comfort.

- Fully adjustable controls and an optional air-ride seat deliver outstanding comfort.

- Extra-large side screens combined with a low-profile�lift arm design provide a wide field-of-view to the side work areas.

- Optional pressurized sealed cab enclosure with sound reduction material and rear-mounted air filter provide a cleaner and quieter operating environment.

- Domed, wide-view glass door option reduces glare and provides optimal visibility to the lift arm, work tool and front work area. Large top, front window provides a clear view of the lift arm in its higher lift positions.

Controls on the Gehl V330 GEN:2 skid loader are ergonomically designed to reduce operator fatigue and increase productivity.

- T-Bar and dual-hand controls are now available.

- Optional electronic attachment control – 14-pin connector for easy operation of all attachments.

- Adjustable joystick handles provide for ease of operator control with minimal of effort, to reduce fatigue.

- New upper-left and upper-right instrument panels provide easy readout and switch access.

- Pilot joystick controls or pilot hand/foot controls provide the ultimate in operator comfort, ease and controllability.

- Infinitely adjustable proportional auxiliary hydraulics.

- Hydraloc™ system applies brakes whenever the operator raises restraint bar, leaves the operator’s seat or switches off the ignition.

Emissions certified Tier IV engines combine power and efficiency on the V330 GEN:2 model.

- Engine consumes less fuel, making a positive impact on the bottom line.

- Automatic glow module engine intake heating system provides superior cold-weather starting.

- Engine has conventional water/ethylene glycol liquid-cooled design.

- Engine warranty, parts and service are handled through normal dealership servicing in conjunction with Gehl parts and service support.

| Make |

Yanmar |

| Model |

4TNV98CT-NMS Tier IV |

| Net Power (kW) @ rpm |

70.7 hp (52.7) @ 2500 |

| Maximum Torque (Nm) |

217 ft.-lbs. (294) @ 1625 |

| Travel Speed – Max with 2-Speed Option (km/hr) |

11.9 mph (19.2) |

When maximum hydraulic power is needed to run demanding attachments, the V330 skid loader is equipped with the tools to get the job done right.

- Higher system pressure delivers more hydraulic muscle to power demanding attachments and deliver superior lifting and breakout forces.

- Standard proportional auxiliary hydraulic control gives the operator the ability to adjust attachment speeds with infinitely adjustable flow control.

- Standard auxiliary detent allows the operator to set attachment for continuous operation.

- Hydraglide™ system allows the lift arm to “float” when transporting loads, minimizing loss of material at faster transport speeds.

- Lift cylinders incorporate cushioning for smoother operation when lowering the lift arm.

- Pilot-controlled hydrostatic transmission with direct engine coupling provides high operating efficiency.

| Auxiliary Hydraulics – Standard (L/min) |

23.5 gpm (89) |

| High-Flow Hydraulics – Optional (L/min) |

35 gpm (132) |

| System Relief Pressure (bar) |

3,200 psi (220.6) |

| Reservoir Capacity (L) |

10.5 gal. (40) |

A full line of Edge attachments and accessories are designed specifically to fill operators’ needs, making their V330 GEN:2 the most versatile machine on the job site. Popular attachments are listed below.

Full Line of Edge Attachments for V330 GEN:2

The V330 GEN:2 skid loader vertical-lift arm design was created for maximum reach, superior strength and optimal operator visibility.

- Additional reach is achieved at trailer loading and unloading heights.

- Self-leveling lift action provides better control of lifting loads.

- Low-profile lift arm design provides outstanding forward and side visibility.

- New single-plane lift-arm design features a heavy-duty timing link, upper-rear channel support and large diameter pivot pins, providing best-in-class vertical and lateral strength and rigidity, as well as exceptional rear visibility.

- Four-point support through dual bucket cylinders and two lift arm stop blocks on the front of the main frame evenly distribute digging forces.

| Height to Hinge Pin – Fully Raised (mm) |

131.2″ (3332) |

| Dump Reach at Full Height (mm) |

32″ (813) |

At Gehl we know ease of serviceability is very important to our customers. The model V330 GEN:2 skid loader is sure to exceed their expectations.

- Large engine cover is hinged and positioned by gas-springs to assist lifting and holding in place, and allows for easy return to closed/operating position.

- Featured cab safety restraint bar for lifting ROPS/FOPS.

- Large rear door easily opens on hinges on right side, allowing full access for servicing and maintenance.

- Remote engine oil filter is on left side; easy access to hydraulic oil filter on right side.

- Entire ROPS/FOPS assembly tilts rearward with a hydraulic lift for easy internal service access.

- Drive chains and axle bearings are sealed systems that require no maintenance.

- Coded wiring takes the guesswork out of electrical system identification.